Publish date: 2026-01-20

Aluminum Nitride (AlN), an advanced ceramic material that integrates high thermal conductivity, electrical insulation, and mechanical strength, is widely utilized in industries such as electronic engineering, mechanical equipment, petrochemical smelting, biology, and optoelectronics. Explore Companion's Aluminum Nitride ceramic products to meet your diverse application needs!

In daily life, electronic devices are ubiquitous—from mobile phones and computers to various smart home appliances. With the rapid evolution of electronic and information technology, the performance of electronic devices continues to enhance, and circuit density and power continue to climb, leading to a significant increase in the heat generated during operation. Therefore, "how to dissipate heat effectively?" has become a critical problem that urgently needs to be solved. Aluminum Nitride ceramics are the ideal solution for this demand.

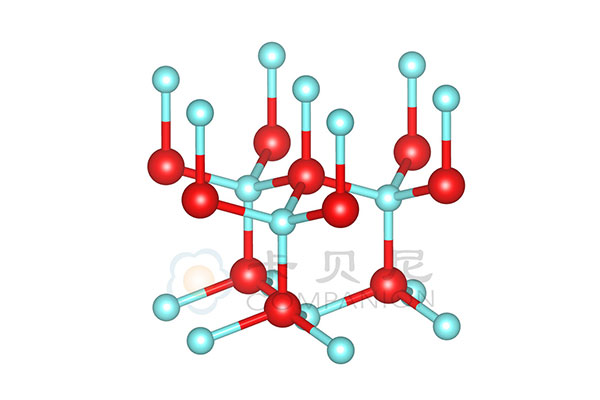

Aluminum Nitride Ceramic (AlN) is an inorganic non-metallic material with Aluminum Nitride as the main crystalline phase. The defining feature of AlN ceramics is their excellent thermal conductivity, which is significantly higher than that of traditional ceramics (such as alumina), enabling the effective conduction of heat away from electronic components to maintain device stability. Furthermore, AlN ceramics possess good electrical insulation, high mechanical strength, a low dielectric constant and dielectric loss, stable chemical properties, non-toxicity, high-temperature resistance, and a low coefficient of thermal expansion.

AlN ceramics have high thermal conductivity, allowing heat to be rapidly conducted from the heat source to the heat sink. This makes AlN an ideal heat dissipation material for high-power electronic devices and LED lighting, effectively reducing the operating temperature of equipment and extending its service life.

The low coefficient of thermal expansion allows AlN ceramics to maintain stable dimensions even under frequent temperature changes, reducing the risk of failure caused by thermal stress.

The high mechanical strength of Aluminium Nitride enables it to withstand significant mechanical stress, making it suitable for use in high-load, complex environments while maintaining the stability of the heat-dissipation structure.

AlN can maintain its physical and chemical stability in high-temperature environments, effectively managing heat generated under extreme conditions.

AlN effectively isolates current, preventing short circuits and ensuring the safety of electronic devices.

In communication equipment (such as 5G base stations), AlN ceramic substrates are used as heat-dissipation materials while providing electrical insulation to support the stable transmission of high-frequency signals.

Aluminum Nitride (AlN) is a covalent bond compound with a high melting point. Its low self-diffusion coefficient makes high-purity AlN powder difficult to fully sinter at conventional temperatures, resulting in insufficient density that affects thermal conductivity. Therefore, to improve the comprehensive performance of AlN ceramics, sintering additives are usually utilised, and various sintering processes are employed, including pressureless sintering, hot-press sintering, and hot isostatic pressing (HIP).

As one of the leading manufacturers of advanced ceramics in China, with twenty years of experience in advanced ceramic material R&D, we provide high-purity, high-performance ceramic products. Companion is also capable of providing non-standard customization based on customer drawings and requirements to satisfy personalized needs.

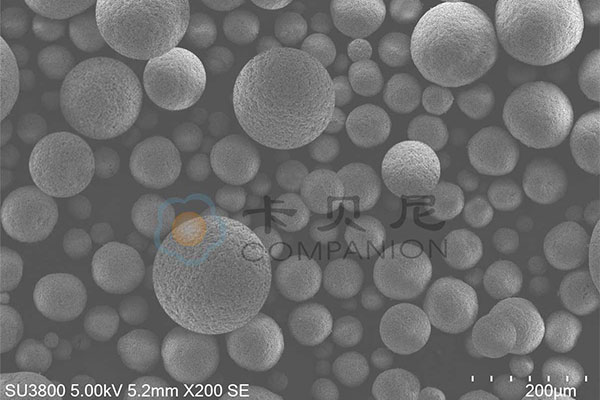

(Microstructure of AlN Granulation Powder)

Our AlN granulation powder features uniform particle morphology and excellent fluidity, which helps improve the density and uniformity of the powder during the sintering process, thereby further enhancing the mechanical strength and thermal conductivity of the finished ceramic product.

AlN nozzles play a key role in micro-nano manufacturing processes within electronic engineering, particularly in scenarios requiring high temperature, high pressure, and high corrosion resistance. Since these nozzles need to precisely regulate fluid flow, velocity, and direction, the choice of material is critical. The high temperature and corrosion resistance of AlN allow these nozzles to maintain a stable shape and size in harsh environments for long periods, thereby ensuring the high accuracy and efficiency of the micro-nano manufacturing process.

(AlN Ceramic Nozzle)

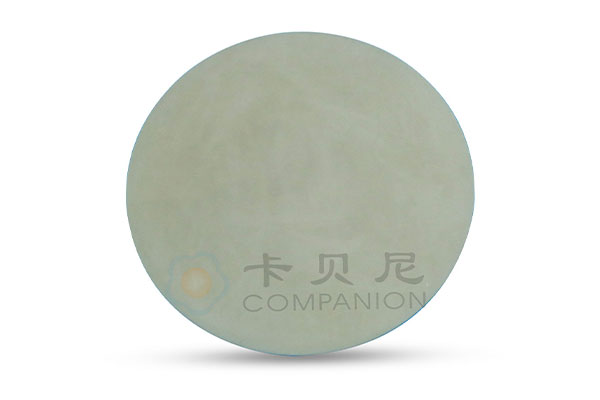

In the field of electronic packaging, AlN ceramic substrates have become the ideal partner for high-power, high-frequency electronic devices due to their excellent properties. The high thermal conductivity of AlN substrates rapidly conducts heat generated by electronic devices, preventing performance degradation or failure due to overheating. Additionally, AlN ceramic substrates offer good electrical insulation and high mechanical strength, providing a stable, reliable platform for electronic devices.

(AlN Ceramic Substrate)

In the precision device manufacturing process, processing techniques require extremely strict temperature uniformity to ensure the high quality of electronic components. To this end, AlN heater plates are key components in this process, using AlN ceramic—which offers high thermal conductivity, good electrical insulation, and plasma resistance—as the primary material to achieve efficient, uniform heating and precise temperature control. Most importantly, the thermal expansion coefficient of AlN is close to that of silicon, ensuring the heater plate maintains stable physical performance even in high-temperature environments and meeting the high demands of precision manufacturing.

(AlN Ceramic Heater Plate)

In electronic engineering, AlN ceramic rings play multiple important roles, primarily covering heat dissipation management, insulation protection, and mechanical support. With excellent thermal conductivity, they can efficiently export the heat generated during the operation of electronic production equipment, effectively reducing the working temperature and improving the overall performance and reliability of the product. Furthermore, as an excellent electrical insulation material, AlN ceramics can effectively prevent short circuits and electric shocks, ensuring the safe operation of equipment.

(AlN Ceramic Ring)

In the wave of rapid electronic engineering progress and the booming development of emerging fields such as 5G communication, the Internet of Things (IoT), and new energy vehicles, Companion, as one of the leading manufacturers in the field of advanced ceramic materials, has accumulated profound experience. We are not only committed to the continuous R&D and quality improvement of advanced ceramic materials but also focus on customer needs, collaborating with customers to develop and provide tailor-made customized advanced material solutions. We strive to meet the strict requirements of every customer for high-performance and high-reliability products, jointly driving innovation and development in the electronics industry!